Egnergy

Reports from system audits and gas quality studiesGas Quality

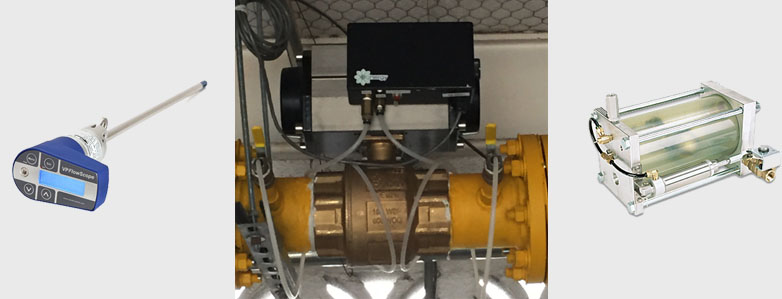

Reports showing Dew Point, oil content, and particle content of compressed air and nitrogen

This report is from a nitrogen system at a large steel mill in North Mexico. The purpose of the report was to find the dew point, pressure and temperature of the nitrogen in the system.

See the nitrogen quality report here

See the nitrogen quality report here

This report is a compressed air quality study that was performed at an electronics manufacturer in Northern Mexico. The purpose was to determine the dew point, oil content, and particle content of the compressed air.

See the compressed air quality report here

This report is a compressed air quality study that was performed at a medical components manufacturing company to try to determine the cause of corrosion of plastic components (filter parts) in the compressed air system.

See the compressed air quality report here

See the compressed air quality report here

This report is a compressed air quality study that was performed at a medical components manufacturing company to try to determine the cause of corrosion of plastic components (filter parts) in the compressed air system.

See the compressed air quality report here